Light enough for any challenge

When it comes to saving lives, there’s no time to stop and think. You have to be able to trust in the quality and reliability of your gear at all times. That’s why we make certain that our search and rescue helmets and our fire helmets are state of the art. Tested in real-life scenarios, they are designed to be robust and durable yet extremely comfortable to wear. While every mission has its uncertainties, your head protection equipment shouldn’t be one of them. When you rely on head protection from Dräger, you know that all the concerns are taken care of.

The Dräger HPS® SafeGuard is the extremely lightweight universal helmet for fire and rescue services. Its innovative design combines optimal protection with the highest levels of wearing comfort. Its sporty look, light weight and tailor-made accessories make the helmet a real all-rounder for any challenge.

There’s a lot to consider when choosing firefighting gear. That’s why we focus on four main capabilities during development and production of our equipment: Usability, Connectivity, Safety+ and Serviceability. Learn how each factor has been applied to our new products and how they can benefit your department.

Internationally approved for all fire & rescue applications while minimizing vision and hearing impairment

Lightweight helmet with optimized wearing comfort and a wide range of accessories

Integrated communication system for increased situational awareness

Easy cleaning and maintenance supporting firefighter health

Learn More here : https://www.draeger.com/en_za/Safety/HPS-SafeGuard

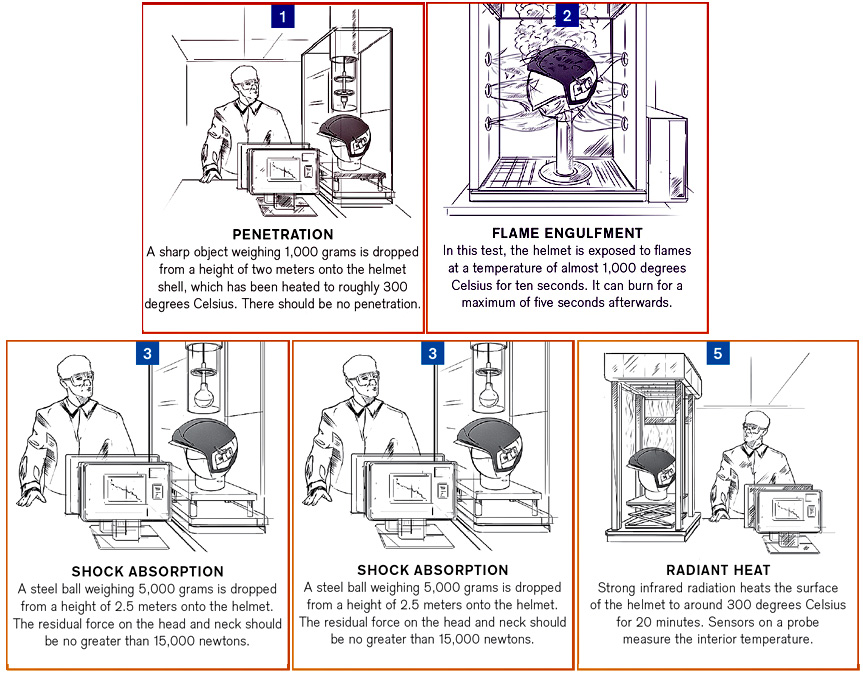

STATUTORY TESTS

(CONDUCTED BY AN INDEPENDENT AND ACCREDITED TESTING ORGANIZATION)

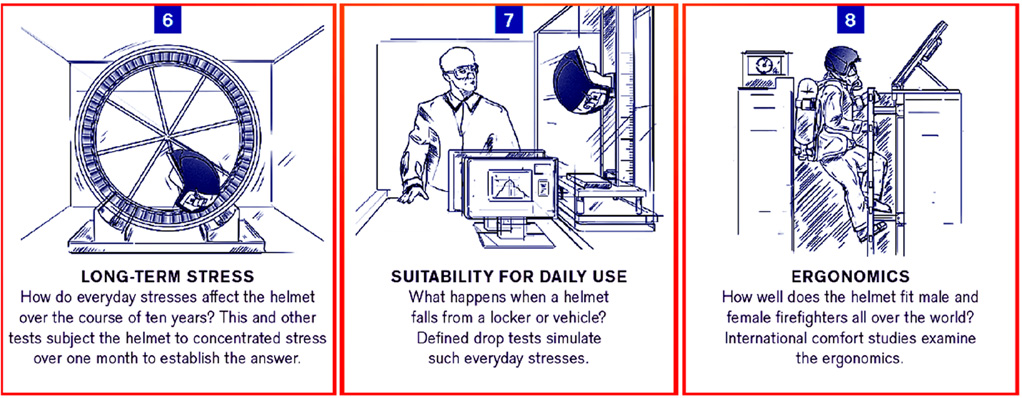

Firefighters’ helmets must pass strict tests in accordance with the relevant standards before theyare approved for use. These scenarios are regularly repeated in Dräger’s own helmet laboratory for quality assurance purposes. It also conducts voluntary long-term tests to assess other factors.

HELMETS UNDER STRESS

Tests subject the firefighter’s helmets to various forms of stress to evaluate their ability to protect the wearer during use. This is shown by the examples from the testing procedures prescribed in accordance with DIN EN 443 (1 to 5). These especially simulate fire and mechanical impact. Such tests are conducted by an independent testing organization prior to approval. In addition, Dräger subjects its helmets to voluntary long-term tests (6 to 8). These evaluate aspects such as ergonomics and behavior in everyday use over the course of several years.

Testing in EN involves broader range of tests in comparison to other standards eg. lateral crushing, flame engulfment test, UV conditioning, retention system effectiveness and strength test etc.

Testing in EN requires higher values, eg. radiant heat, shock absorption, combined tests with radiant heat and mechanical impacts (shock and penetration) etc.

Testing in EN requires system testing including all accessories, eg. eye and face protection, neck protection, torches, communication etc. which have to fulfil all and same requirements as the helmet.

Learn More : https://www.draeger.com/en_za/Fire-Services